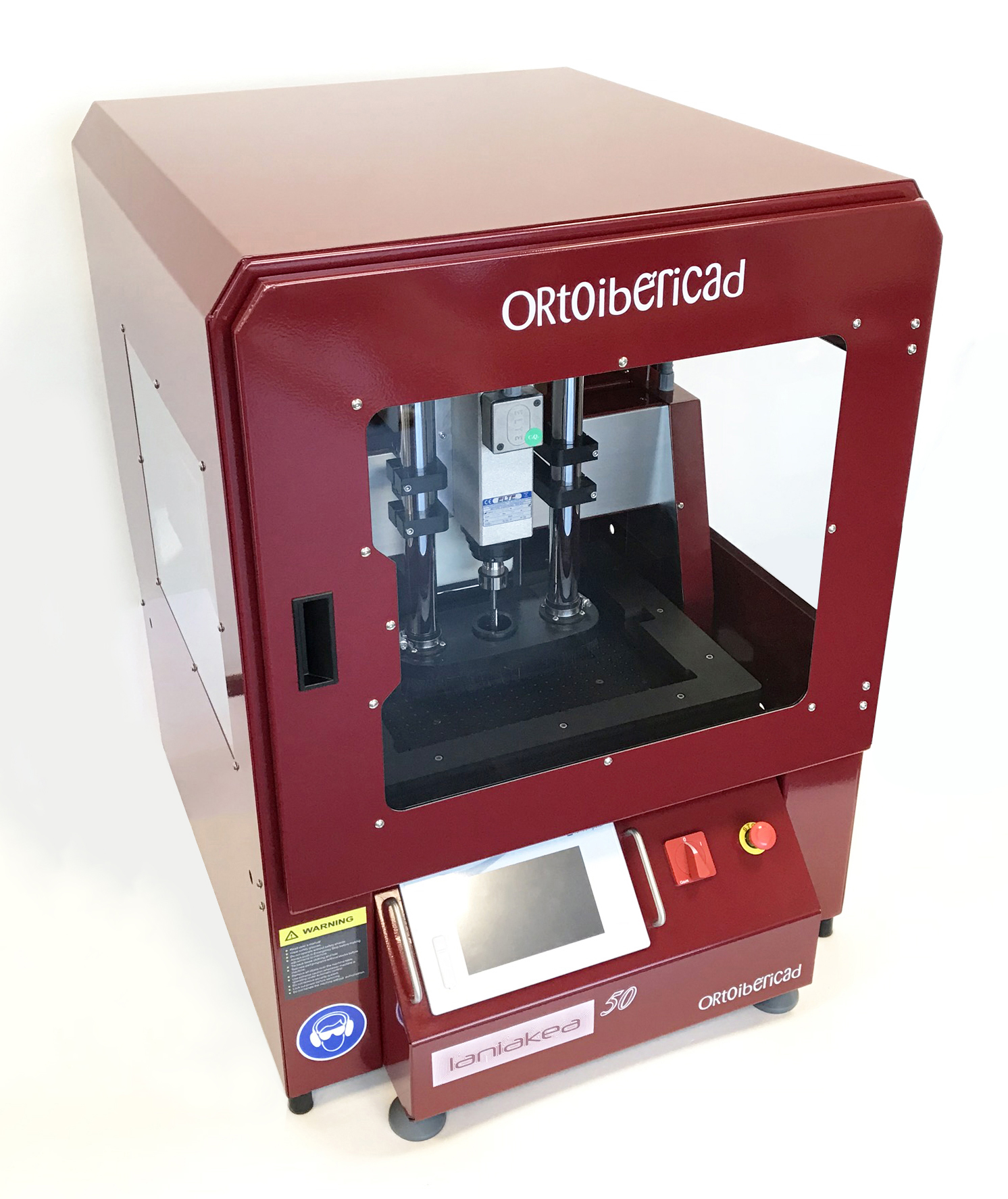

Laniakea 50

– Vacuum sectorized table for the fastening of EVA block.

– Linear guides with 15 mm ball recirculation skids without looseness.

– Transmission by spindles with recirculation nuts (balls) on all axes.

– High travel speed 15000 mm / min

– Resolution 0.005 mm.

– Sanyo Denky stepper motors high torque 30 kg / cm

– Integrated TextComputer with 7 “touch screen.

– Integrated installation for chip aspiration system.

– End of stroke detection on all axes.

– Z-axis zero probe.

– Dimensions of the table: 330×300. Z axis: 80 mm.

– ELTE 1,5 HP brushless milling motor with 24000 rpm.

Two versions are sold with the same benefits, with the only difference that one of the models has a fairing that closes the milling area, thus controlling access to that area through a glass window door, in addition to controlling a better aspiration and less noise.

| Reference | Concept |

| LK-1100-100 | Laniakea 50 milling machine (220v) integrated in Pi.Cas.So. |

| LK-1100-120 | Aspiration for Laniakea 50 |

LK-1100-150 Capsule closure / Case Laniakea 50